WHY IS BUYING A DPF/FAP FILTER AND SCR CATALYST CLEANING MACHINE A RIGHT INVESTMENT?

No diesel car that does not have a working DPF filter will be able to pass MOT. Which means every driver will need a DPF filter cleaning service.

Have your own service?

Or do you want to start your own business?

Buy a DPF/FAP filter and SCR catalyst cleaning machine.

For your potential customers, cleaning DPF/FAP filters and SCR catalytic converters means saving money and time. The service you provide is aimed primarily at:

• improving engine performance,

• saving in fuel consumption,

• as well as environmental protection.

Machine washing restores the original function of clogged DPF filters and catalytic converters, which is to reduce the emission of harmful gases from the engine into the atmosphere.

The complete process is performed on one machine and takes 90 minutes for passenger vehicles, and 150 minutes for the cargo program and work machines. This method ensures the efficiency of the DPF filter and catalyst, compared to other methods it gives incomparably better results.

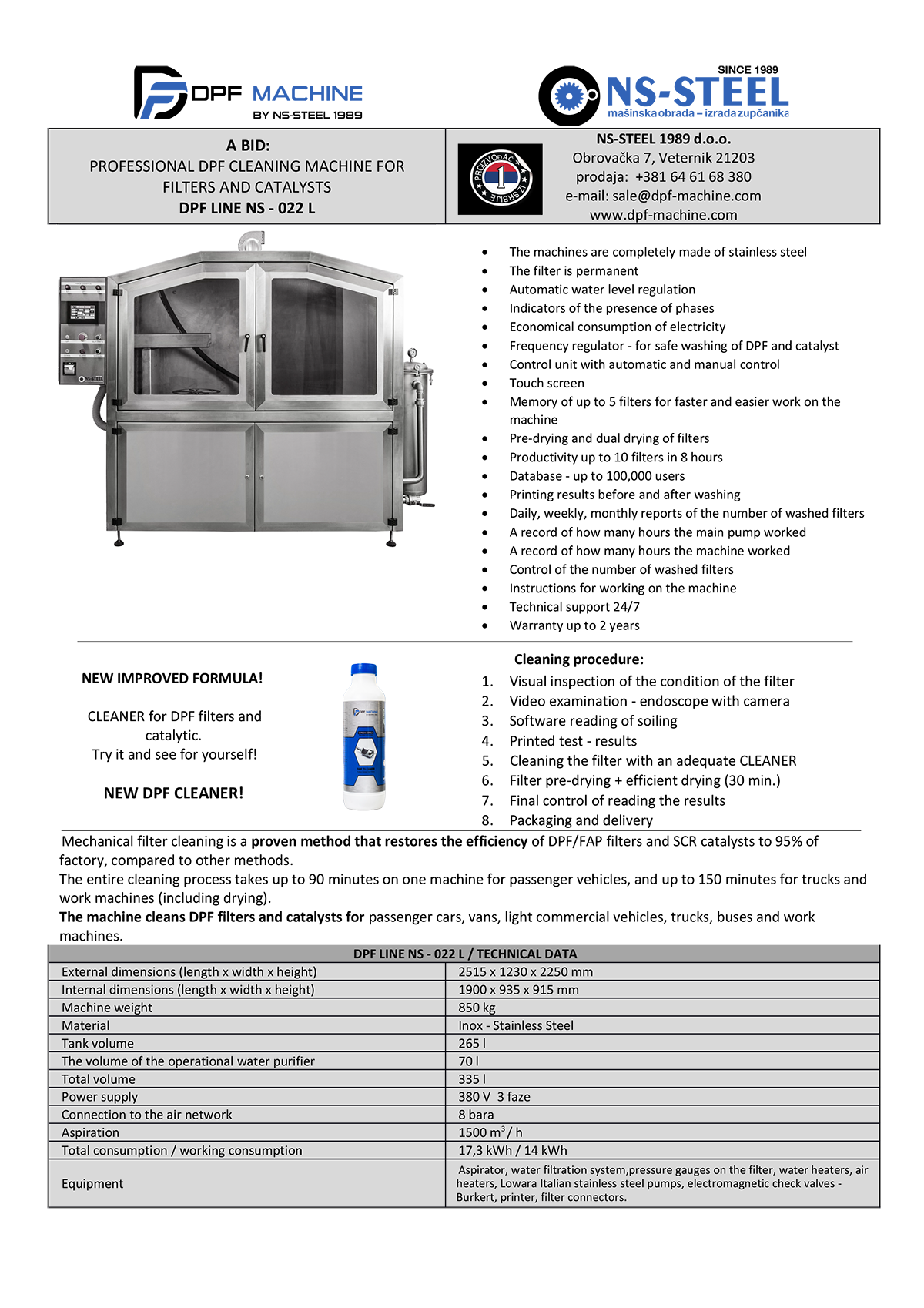

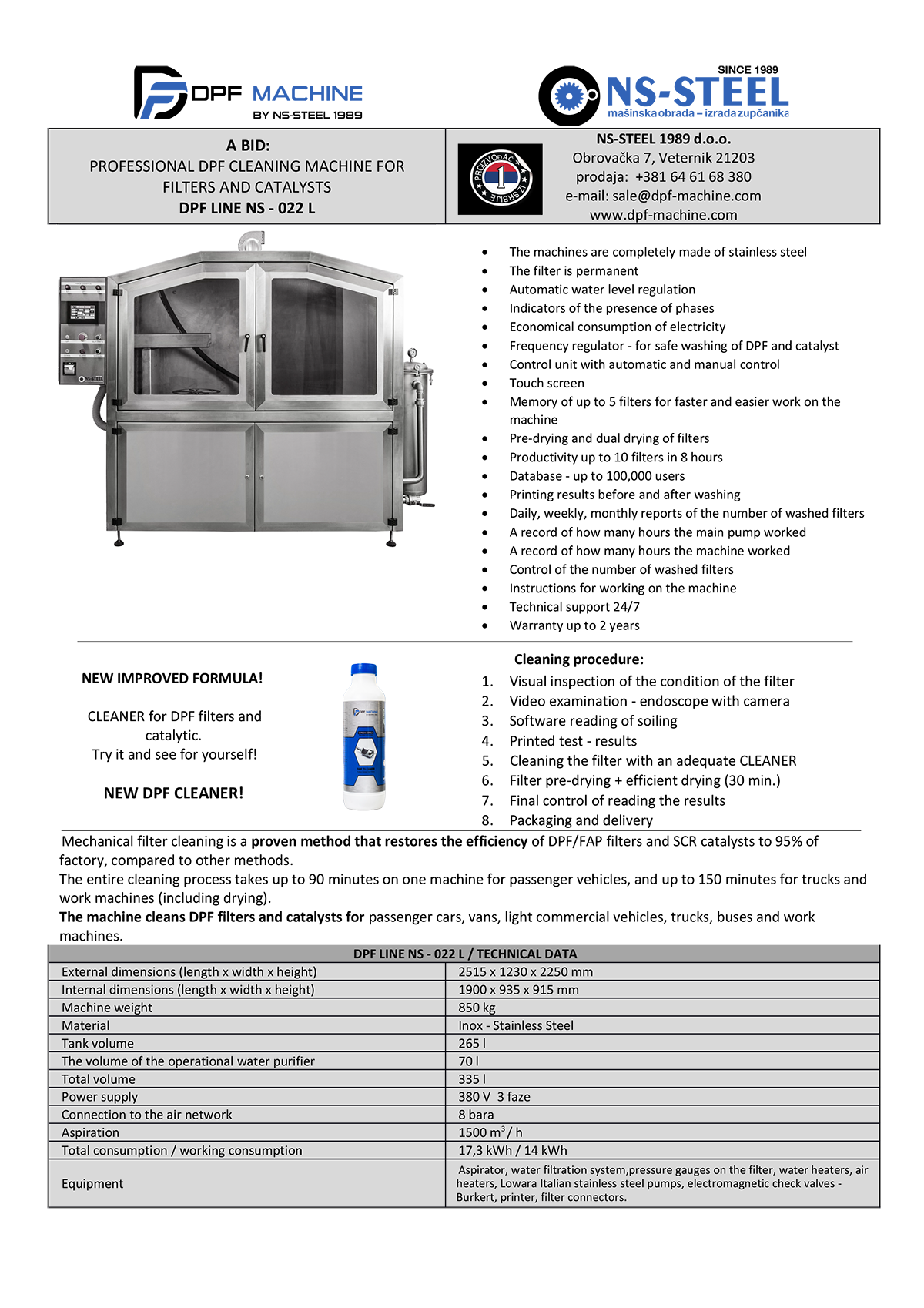

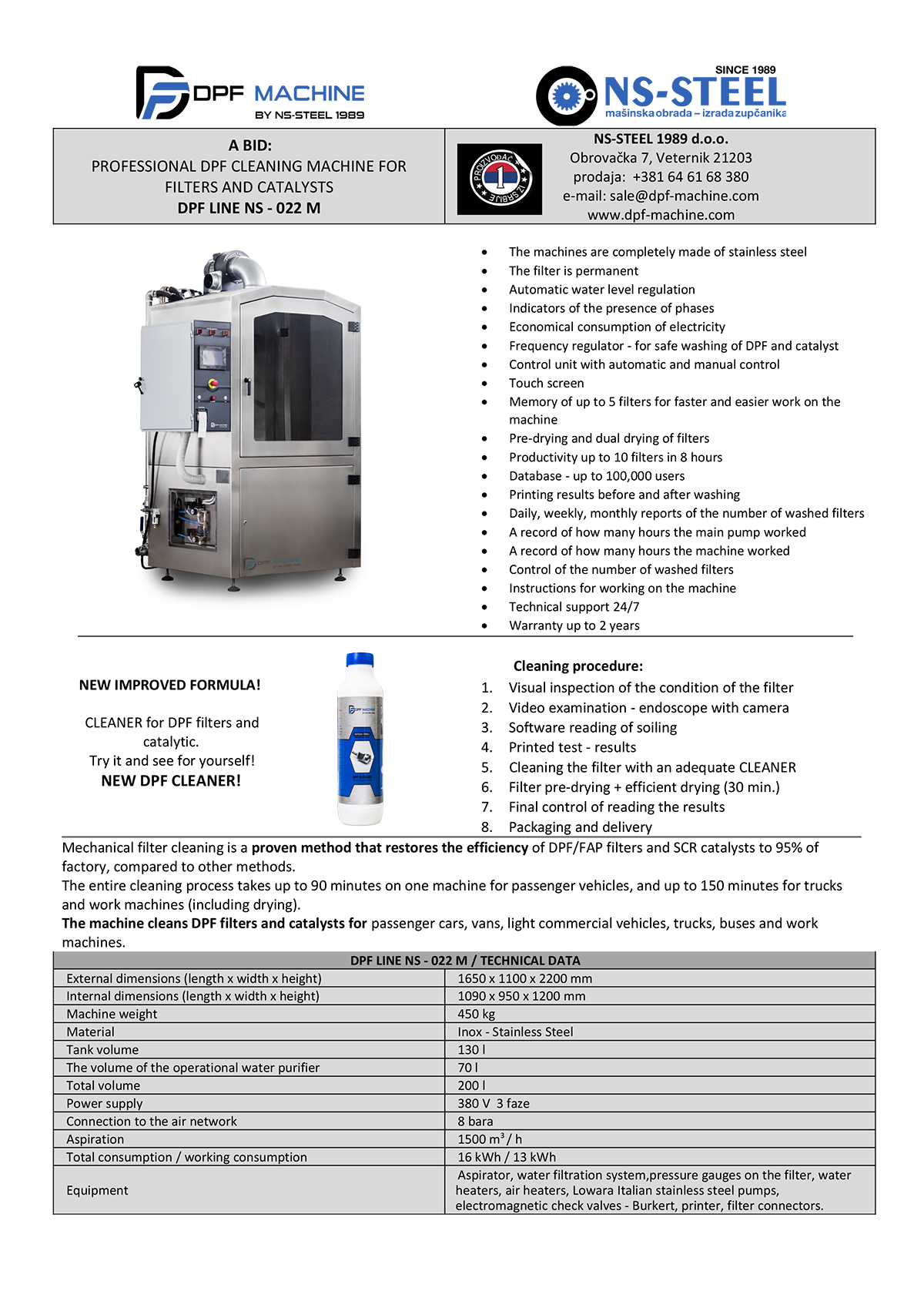

The machines in our offer are designed on the basis of many years of experience by a professional team of engineers. Proven components, the highest quality materials were used, and the software was made according to our requirements and the practical experience we have in the field of machine cleaning of filters and catalysts.

Machine washing of the DPF/FAP filter and SCR catalyst is the only real method that ensures effective cleaning, restores the function of the DPF filter and catalyst to factory values. What is very important during the washing process is that the DPF filter is not damaged and the EURO NORM is not lost, which is the most important thing.

DPF/FAP filters and SCR catalysts are cleaned on the following motor vehicles:

• passenger and van vehicles,

• light commercial,

• semi-trucks and trucks,

• working machines.

Which means that the number of potential clients is very large.

WHY SHOULD EVERY SERVICE SHOP HAVE A DPF/FAP FILTER AND SCR CATALYST CLEANING MACHINE?

• Any turbine failure requires DPF cleaning.

• When there is a malfunction or the EGR valve is dirty, it is necessary to clean the DPF as well.

• Improper fuel dispersion in the nozzles leads to increased clogging of the DPF filter.

• When the car has traveled between 150,000 km and 200,000 km, the light that signals that the DPF is clogged usually comes on.

• The machine is adequate and adapted for cleaning the filters of cargo and passenger programs.

This is a sample text. You can click on it to edit it inline or open the element options to access additional options for this element.

WHAT SHOULD YOU KNOW ABOUT OUR DPF/FAP FILTER AND SCR CATALYST WASHERS?

• The machines are completely made of polished INOX class I;

• They have a control unit with automatic and manual control, easy to use;

• They also have modern software with a modern interface;

• The FREQUENCY REGULATOR saves the main pump and regulates the filter washing pressure, which is very important because it protects against damage to the DPF during washing. Machines that do not have pressure regulation do not provide SAFE washing of the DPF and catalytic converter;

• The pump is completely made of INOX (LOWARA Italian - by A Xylem brand);

• The machines have magnetic and non-return valves that manage the operations during its operation of the German brand BURKERT;

• German and Japanese electronics were used to equip the machines;

• Thanks to the 7" touchscreen, the machine is easy to use;

• The machine has pre-drying and dual drying of exceptional quality. Drying reduces labor time and saves money by ensuring that the filter is returned to the owner completely dry without fear of car breakdown;

• The filter on the machine is permanent and does not change, its maintenance is independent;

• Water capacity in the machine:

M model - 200l (also supports washing of trucks).

L model - 335l;

• It has a readout of filter flow results (printed written result) before and after washing - Italian printer - shows the client the results of the service;

• It provides economical power consumption achieved by installing quality components;

• Contains an indicator of current consumption by phases;

• It has connectors for connecting filters (they are included in the price of the machine);

• The memory of up to 5 filters speeds up the process of testing and washing;

• The capacity of the user database is up to 100,000;

• Contains instructions for working on the machine;

• They fall under INDUSTRIAL machines whose components are adapted and resistant to workshop working conditions where there are certain impurities, moisture, inadequate temperature, etc.;

• We also offer the appropriate agent-detergent necessary for high-quality filter washing, a recognized, certified and frequently used product throughout Europe. DOES NOT DAMAGE THE INTERIOR OF THE DPF.

With the NEW series of machines in 2022, you also get 2 years of WARRANTY!

WHAT DOES THE DPF FILTER AND CATALYST CLEANING PROCEDURE LOOK LIKE?

1.First, a visual inspection of the condition of the filter is performed.

2.Then a video examination, which is done with an endoscope camera.

3.Soiling is read by software.

4.The results are found on the printed test.

5.The DPF/FAP filter and the catalytic converter are cleaned with an appropriate agent.

6.After that, the filter is pre-dried and effectively dried for 30 minutes.

7.Before the end, a final control of the reading of the results is done.

8.Finally comes packaging and delivery.

The machine is in the industrial class, it has all the necessary certificates for export to the EU. It has a high degree of reliability and daily washing and drying capacity.

With the machine, you get a detergent (appropriate chemistry) for washing the filter with a certificate and all necessary safety certificates.

There are two models on offer, and you can find out the price of the washing machine for DPF/FAP filters and SCR catalysts by calling the numbers + 381 646 168 380 or by sending an inquiry to: sale@dpf-machine.com.

The NS-STEEL 1989 machining center with decades of experience and tradition is engaged in the provision of machining services, manufacturing of toothed parts - gears, CNC cutting, production and servicing of machines.

The company also has a service for machine washing and cleaning of DPF/FAP filters and SCR catalysts.